Application of weighing module in automatic batching system

Release date:2022-04-29 Source:ZHONG KE KE ZHENG Views:873

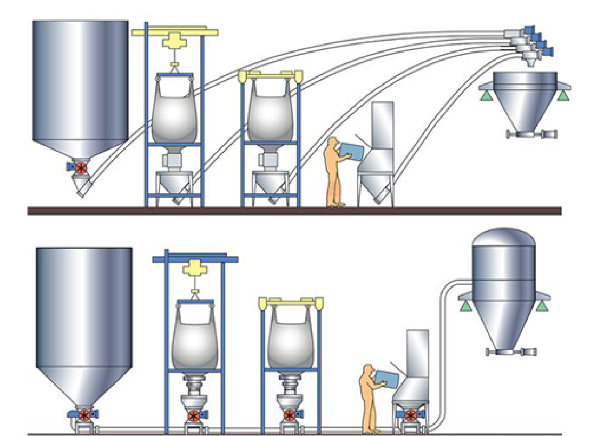

Automatic batching and batching system consists of automatic feeding system, raw material warehouse, a variety of batching metering machine, material conveyor, mixer, electrical control system and so on. Automatic mixing operation according to preset parameters and process requirements. Automatic batching system is widely used in food (medicine), chemical, new materials, new energy, environmental protection, building materials and many other industries of automatic batching.

Powder and bulk solid applications, such as food and pet food formulations, have incorporated automatic batching weighing and batching systems into their manufacturing processes, which help simplify operations.

Automated batching weighing and batching systems are widely used in food, pharmaceutical and chemical materials such as flavourings, active ingredients and catalysts. These automated controller systems enable manufacturers to increase production and reduce labor and material changes. These automated systems also simplify batch tracking and production record keeping. However, with these automated systems, the ingredients that make up a batch or mixture are increasingly concentrated in order to minimize the associated transportation and storage costs. These more concentrated ingredients have escalated the need for highly accurate weighing systems. Often, there is a trade-off between using a scale large enough to weigh the formula and a scale small enough to be accurate. A clear understanding of automatic batching weighing and what a batching system can do is necessary to design an optimal system for accurate batching for your application.

Construct a qualified weighing system

Several factors come into play when accurate weights need to be achieved in automatic component weighing and batch systems. These factors should be considered when purchasing automatic weighing and batch systems, and include the number, size and installation of weighing sensors, weighing instruments, scales, the size of feeders used to feed materials into the scales, the control system for handling recipe automation, the cycle time or process speed required, and the environment in which the scales are installed.

Environment: A very important factor that is often overlooked is the environment in which the weighing system will be installed. Environmental conditions that can affect balance accuracy include exposure to excessive vibration, airflow caused by door opening and closing, pressure differences caused by the delivery system, and temperature fluctuations. If the scale bounces up and down 20 g increments due to other process equipment operating in the service plant area, there is no benefit in setting a scale with 10 g accuracy. Ensure that system fluctuations do not exceed the target accuracy that you are trying to achieve for your process. In the case of cyclic vibrations, such as those caused by a blender or other equipment, you may be able to actively filter out the vibration signal electronically. Fluctuations in the scale of the unstable (such as a truck or someone to open and close when I shut the door, if the scale is installed on the solid structure, is not affected by vibration near, if scale by metal, glass, plastic or cloth cover properly protected, thus block airflow of movable balance, you can minimize the fluctuations.

Load cell: In most modern applications, a load cell, called a load cell, is usually an electronic strain gauge, such as the one shown here. When force is applied to the element, deflection of the load-bearing element is measured by standard strain gauge technique. The load-bearing elements that are deflected must be highly repeatable to the degree of deflection of a given load and the ability of the load-bearing elements to return to their original position must be highly repeatable. A typical strain gauge is combined with a load bearing element, and when the load bearing element is bent, the resistance of the meter changes.