Design Customization

Engineering design is divided into scheme design, preliminary design, technical design and construction drawing design according to different work process and depth. The division of design stages of different engineering projects can be different. For example, for large and complex engineering projects, scheme design should be carried out first, and then preliminary design, technical design and construction drawing design should be carried out through scheme selection. We provide one-stop services from scheme planning, design, production, installation, commissioning, training, operation, acceptance to after-sales. According to the depth of customer needs, this service can be divided into: routine consultation, simple scheme, technical document design, simulation design, 3D design, Party B's bid submission, Party A's bidding document submission, project budget, project construction drawings, etc. Our company undertakes the preliminary design, system integration and construction of the project, and turnkey project.

MORE

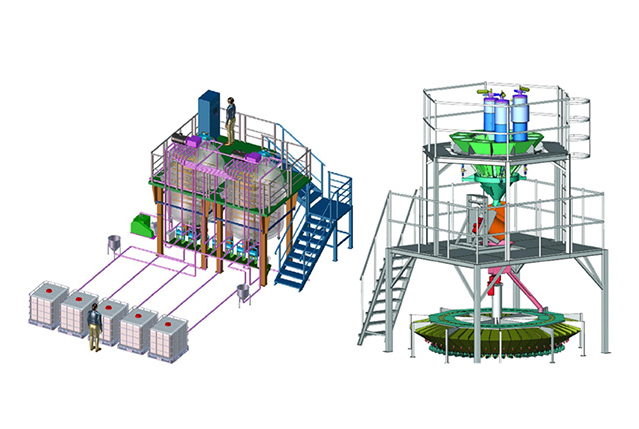

Automatic Batching

Automatic weighing batching control system, also known as automatic batching production line system. It is usually composed of an automatic batching electrical control system, a controlled feeding device (equipment), and a monitoring system. Compared with artificial ingredients, it can not only save a lot of labor cost and labor intensity in production, reduce the harm of the environment to the human body, but also improve the stability, accuracy and efficiency of end products, bringing huge benefits to production enterprises. Zhongke Kezheng provides automatic weighing and batching equipment and system solutions for many enterprises, and can customize a complete set of solutions for your production line. Automatic batching production line system is widely used in cement, steel, glass, coal mine, pharmaceutical, feed, building materials, plastic, rubber, compound fertilizer, brick, food and many other industries. This set of production lines are widely used in automatic batching and packaging production lines of various materials and industries. It is suitable for automatic weighing and weighing of different materials, powder materials, granular materials, irregular materials, and liquid ingredients in the mixing process; only need to manually add 2 More than 30 kinds of materials are put into each silo, and automatic feeding equipment can also be added to automatically transport the materials to the corresponding silo. The computer control system automatically puts various materials into the weighing scale according to the preset ratio. In the weighing system, the weighing system will automatically add the ingredients according to the proportion of each material. After each batching is completed, the bucket elevator will automatically lift the material into the mixer for mixing. Referring to the supply packaging system in the storage bin for automatic quantitative packaging.

MORE

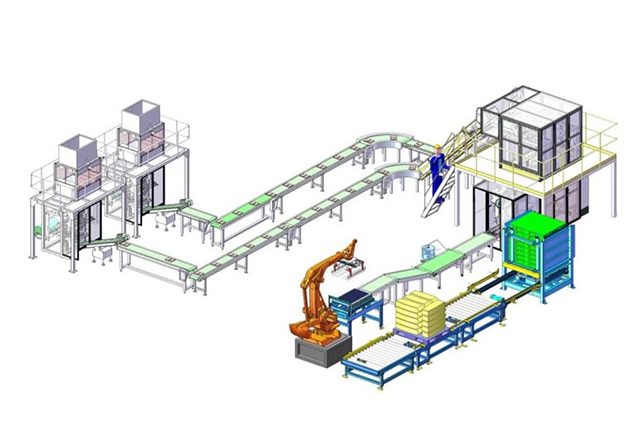

Packaging Palletizing

The automatic metering and packaging system is widely used in the automatic quantitative packaging of various packaging bags, such as paper bags, plastic bags, woven bags, etc. Its products are widely used in petrochemical, plastic, rubber, fertilizer, grain, food, medicine, feed, building materials, feed, environmental protection, minerals, new materials, metallurgy, ports, logistics and other industries. It is a full-process automation equipment that integrates automatic quantification, packaging, labeling and sealing (seam) transportation, weight detection and other equipment for bagged items such as materials. Suitable for large bags of 25kg-50kg nylon woven bags, paper-plastic composite bags, etc. are all packed in standard bags, which can realize continuous production and high-yield automatic bagging (sleeves) measurement packaging. The equipment can be combined with weighing scale conveyors and automatic sewing machines. Closely cooperate to complete the integrated automatic operation of bagging, weighing, bagging, conveying and sewing. Free people from heavy and repetitive work. The robot palletizing production line is widely used in the palletizing of various bags and boxes. It is convenient and flexible, and has a wide range of applications. It can be used with multiple mobile lines and has a simple structure. It is equipped with different manipulators (fixtures, tooling) to complete the corresponding work. According to the shape of the object, different manipulators are installed to cooperate with the palletizing, which has the characteristics of strong changeability and wide application. Currently used by many industries. ● Robotic palletizing unit for bags Uses: It is widely used in the automatic palletizing of bags in the industries of grain, feed, fertilizer, building materials, chemical raw materials, etc. Automatic sorting (arranging) and stacking of layers, supporting automatic pallet supply system and unloading conveying, only need forklift to remove the unloading pallet. Select the model of the brand robot according to customer requirements, such as: ABB series robots, KUKA series robots, Kawasaki series robots, FANUC series robots, Fuji series robots, etc. The matching conveyor line can be customized according to the on-site connection. ● Box-loading robot palletizing unit Uses: It is widely used in the automatic palletizing of boxes in food, beverage, edible oil, clothing, parts, chemical raw materials and other industries. Waiting for rows, automatic sorting (arranging) and stacking of layers, supporting automatic pallet supply system and unstacking conveying, only forklifts need to remove the unstacking pallets.

MORE

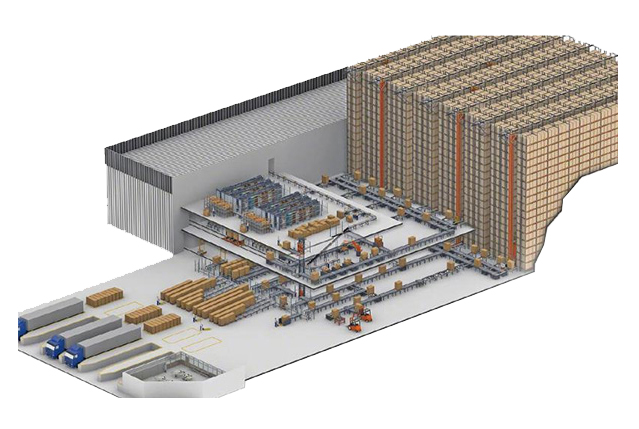

Warehousing Logistics

Automated three-dimensional warehouse (AS/RS) is composed of three-dimensional racks, track stackers, pallet conveyor systems in and out of storage, size detection bar code reading systems, communication systems, automatic control systems, computer monitoring systems, computer management systems and other such as A complex automation system composed of auxiliary equipment such as wire and cable bridge power distribution cabinets, trays, adjustment platforms, and steel structure platforms. The intelligent loading and unloading truck system is mainly used to realize the purpose of automatic loading and unloading of the logistics and transportation of packaged items. It is suitable for automatic loading and unloading of traditional warehouses and automatic three-dimensional warehouses. According to the preset data, the loading and unloading operations are automatically completed without the need for personnel to be on duty.

MORE

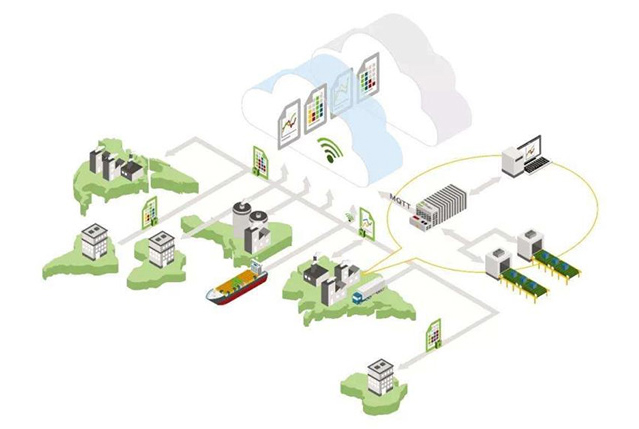

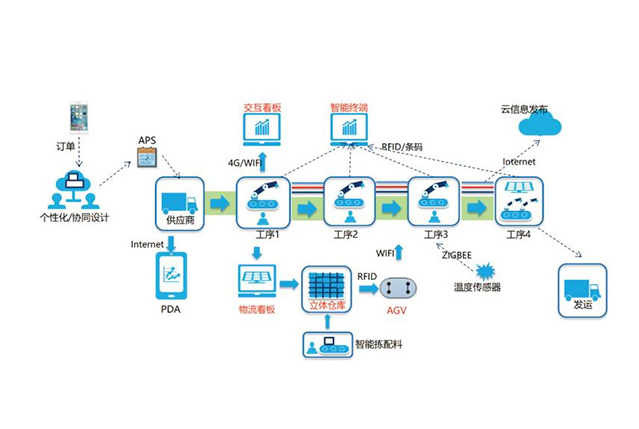

Information System

The industrial control system is a business process control system composed of various automation control components and process control components that collect and monitor real-time data to ensure the automatic operation, process control and monitoring of industrial infrastructure. Its core components include data acquisition and monitoring system (SCADA), distributed control system (DCS), programmable logic controller (PLC), remote terminal (RTU), human-machine interface equipment (HMI), and the interface technology.

MORE