Design Customization

Engineering design is divided into scheme design, preliminary design, technical design and construction drawing design according to different work process and depth. The division of design stages of different engineering projects can be different. For example, for large and complex engineering projects, scheme design should be carried out first, and then preliminary design, technical design and construction drawing design should be carried out through scheme selection. We provide one-stop services from scheme planning, design, production, installation, commissioning, training, operation, acceptance to after-sales. According to the depth of customer needs, this service can be divided into: routine consultation, simple scheme, technical document design, simulation design, 3D design, Party B's bid submission, Party A's bidding document submission, project budget, project construction drawings, etc. Our company undertakes the preliminary design, system integration and construction of the project, and turnkey project.

Tel:

(+86) 0551-65650713

Product features

Brand advantage: The design scheme of large-scale projects can be entrusted or jointly designed by the Chinese Academy of Sciences, which can improve the quality and gold content of the project while ensuring the delivery of the design scheme.

Improve project success rate. Through integrated design, 3D model construction, and even simulation video drills, the project success rate is greatly improved, and project risks are avoided and reduced.

Create high-quality projects. Thanks to the rich multi-industry construction experience and perfect supplier system, the integrated system integration solution designed by the company can help enterprises to create exemplary high-quality projects, enhance the influence of enterprises, and improve the success rate of enterprise project awards and compensation applications.

Reduce total project cost. Based on the proprietary technology and professional technology mastered by the company and the Chinese Academy of Sciences, technical optimization is carried out in the design of the scheme, and the investment is reduced while ensuring the realization of the function. At the same time, the total cost of project investment is further reduced through the application of project awards and subsidies.

Related Products

Non-standard system engineering

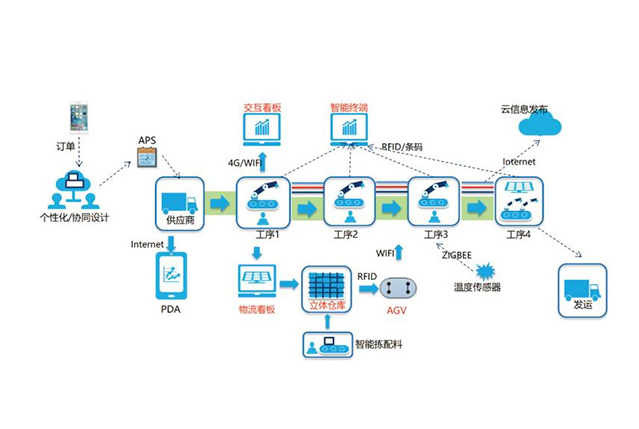

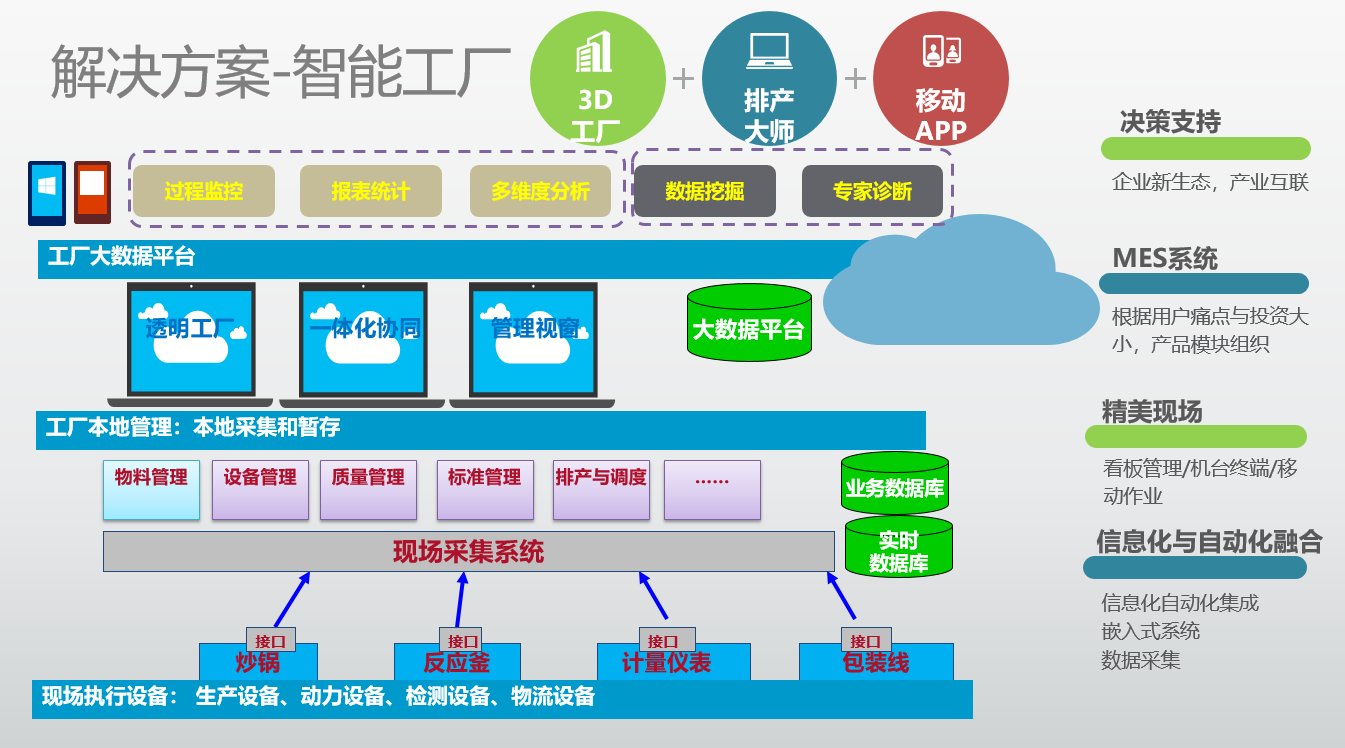

The basic framework of a smart factory includes key components such as intelligent decision-making and management systems, enterprise virtual manufacturing platforms, and intelligent manufacturing workshops.

A smart factory consists of a virtual digital factory in cyberspace and a physical factory in a physical system, with the ability to collect, analyze, judge and plan autonomously. Inference and prediction through the entire visualization technology, using simulation and multimedia technology, will extend the display design and manufacturing process in the real world. Each component of the system can form the best system structure by itself, which has the characteristics of synergy, reorganization and expansion.

Among them, the physical factory has deployed a large number of workshops, production lines, processing equipment, etc., providing hardware infrastructure and manufacturing resources for the manufacturing process, and is also the final carrier of the actual manufacturing process; the virtual digital aluminum factory is the digitization of these manufacturing resources and manufacturing processes. model, while the physical factory for production. Prior to this, the entire manufacturing process was fully modeled and validated. In order to realize the communication and integration of the physical factory and the virtual digital factory, the manufacturing unit of the physical factory is also equipped with Dali's intelligent components for status sensing and manufacturing data collection.

Zhongke Ke is relying on the technical support of the Chinese Academy of Sciences, and can undertake the design, construction and EPC of smart factories. Welcome to discuss cooperation!

Video case

Online