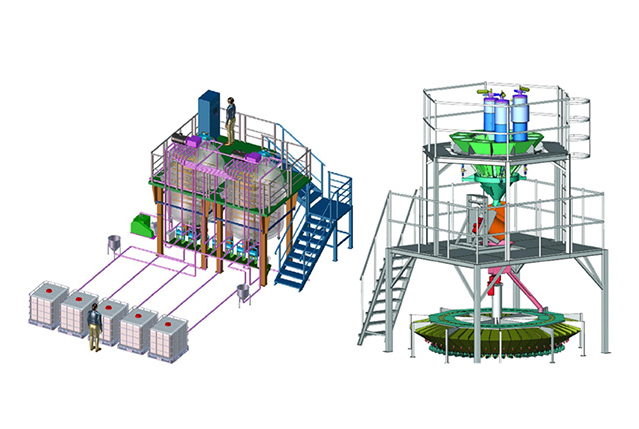

Automatic Batching

Automatic weighing batching control system, also known as automatic batching production line system. It is usually composed of an automatic batching electrical control system, a controlled feeding device (equipment), and a monitoring system. Compared with artificial ingredients, it can not only save a lot of labor cost and labor intensity in production, reduce the harm of the environment to the human body, but also improve the stability, accuracy and efficiency of end products, bringing huge benefits to production enterprises.

Zhongke Kezheng provides automatic weighing and batching equipment and system solutions for many enterprises, and can customize a complete set of solutions for your production line. Automatic batching production line system is widely used in cement, steel, glass, coal mine, pharmaceutical, feed, building materials, plastic, rubber, compound fertilizer, brick, food and many other industries.

This set of production lines are widely used in automatic batching and packaging production lines of various materials and industries. It is suitable for automatic weighing and weighing of different materials, powder materials, granular materials, irregular materials, and liquid ingredients in the mixing process; only need to manually add 2 More than 30 kinds of materials are put into each silo, and automatic feeding equipment can also be added to automatically transport the materials to the corresponding silo. The computer control system automatically puts various materials into the weighing scale according to the preset ratio. In the weighing system, the weighing system will automatically add the ingredients according to the proportion of each material. After each batching is completed, the bucket elevator will automatically lift the material into the mixer for mixing. Referring to the supply packaging system in the storage bin for automatic quantitative packaging.

Tel:

(+86) 0551-65650713

Product features

Monitoring function: Detect and monitor parameters such as instantaneous flow, daily accumulation, monthly accumulation, and annual accumulation in the batching process of the belt weighing;

Screen display: Through the computer display, the operation status of the relevant control parameters in the batching process can be displayed, and the real-time batching curve and table can be displayed;

Printing management: The ingredient report can be printed at any time for saving and querying;

Data processing: The batching system can automatically process the collected signals and output them to the corresponding control quantities;

Communication function: two-way data and information exchange between industrial computer and PLC and instrument;

Control function: According to the corresponding set value before operation, the normal operation of the equipment is automatically controlled, including PID adjustment;

Alarm function: The host computer will alarm various parameters overrun or abnormal equipment status in the form of picture and sound and light signal.

Advantages compared with manual batching

Automatic quantitative feeding according to the preset program, with high measurement accuracy, high efficiency and good consistency;

It can realize timing and quantitative automatic feeding according to the batching process requirements;

Manual feeding raw materials can be fed by scanning barcode, error-proof system, and the order of feeding can be set in the batching process;

A variety of recipes can be preset for storage, and there is no need to reset the recipe, and it is very convenient to retrieve;

Adapt to harsh environments (ambient temperature, toxic odor, dust) unmanned automatic operation;

The formula can be kept secret in different levels, and password management can be realized;

The function of formula printing can be realized, and the historical data records can be checked;

Access to the whole production line before and after batching equipment, can realize automatic control and remote control;

The configuration and requirements of this set of production lines can be designed separately according to the process requirements.

Three ways of ingredients

Static batching mode

Applicable to sites without continuous batching requirements, batching can be carried out in batches, and a certain time interval is allowed between batches. These sites do not have high requirements for batching time, and have strict requirements on the composition ratio of a single batch of materials. The proportion of materials is based on The process requirements are relatively fixed within a period of time, each batch of materials is composed of a variety of materials, and the relative dynamic batching accuracy is much higher.

Dynamic batching mode

The dynamic batching mode is suitable for the site where continuous batching is required. The on-site requirements for the continuity of batching are relatively high. Generally, it is not allowed to stop the intermediate batching, and the requirements for the proportioning of various materials are relatively strict. The measurement of dynamic batching system generally adopts electronic belt scale or nuclear scale as the measurement equipment, and the host has PID adjustment and alarm function, which can realize automatic control. The batching scale communicates with the control host through the field bus.

Dynamic and static combination mode

Some industries have special process requirements in batching, and need dynamic and static combined mode batching to meet the final process requirements. According to the batching process requirements, the parallel method can be adopted in the control process, which can meet the requirements of high-precision micro batching and continuous batching of large proportions of materials, so it can save batching time and meet the requirements of batching speed and batching accuracy.

technical parameter

| Material variety | Main ingredient (aniseed) | 1-8 kinds | Adaptation: granular material, powdery material, mixed material | Remark | ||

| Accessories(small materials) | 1-10 kinds | Adaptation: granular material, powdery material, mixed material | According to the characteristics of the material and the process requirements: the structure, height and floor space of the equipment, the batching speed and accuracy 、control system. | |||

| liquid (water) | 1-3 kinds | Adaptation: water, oil, liquid mixture, slurries, etc. | ||||

| Ingredients | 0.5 - 50 tons/hour | batching speed | 15-20 batches/hour | accuracy | 0.2% | |

| Power/Power Consumption | AC:380V±10% / 50Hz | Power: 5-20KW | Gas source | 0.6Mpa | Determine the power consumption according to the configuration and output of the entire line equipment | |

Video case

Online