Warehousing Logistics

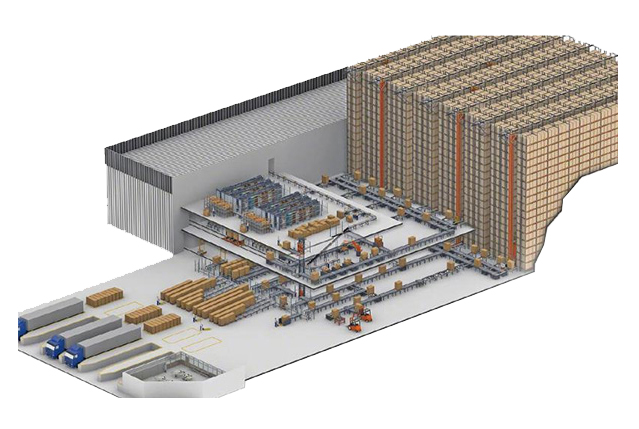

Automated three-dimensional warehouse (AS/RS) is composed of three-dimensional racks, track stackers, pallet conveyor systems in and out of storage, size detection bar code reading systems, communication systems, automatic control systems, computer monitoring systems, computer management systems and other such as A complex automation system composed of auxiliary equipment such as wire and cable bridge power distribution cabinets, trays, adjustment platforms, and steel structure platforms.

The intelligent loading and unloading truck system is mainly used to realize the purpose of automatic loading and unloading of the logistics and transportation of packaged items. It is suitable for automatic loading and unloading of traditional warehouses and automatic three-dimensional warehouses. According to the preset data, the loading and unloading operations are automatically completed without the need for personnel to be on duty.

Tel:

(+86) 0551-65650713

Product features

Seamless docking: The automated three-dimensional warehouse can be docked with the production line, and can be seamlessly docked with the enterprise management system ERP;

Meet a variety of models: meet the needs of loading and unloading vehicles of various models (suitable for loading and unloading with or without pallets), no need to modify the vehicle or add equipment;

Strong adaptability: online, transit, traditional library, automatic stereo library can be;

Unmanned operation: The whole process of unmanned operation has a variety of information transmission, which can realize MES (data collection and preset).

Related Products

1. Stereo library

AS/RS (Automated Storage and Retrieval System), which is usually referred to as an automated storage system, is composed of high-level three-dimensional shelves, stackers and other handling systems, conveying systems, AGVs, information identification systems, and computer control. System, communication system, monitoring system, management system, etc.

2. Loading and unloading system

The automatic loading system can realize the automatic loading process of bag, box and other materials. It completely replaces manual loading of various bagged and boxed materials, saves a lot of labor and labor costs, and improves loading efficiency. This system uses the vision system and laser sensor to assist in locating the vehicle and its related dimensions, and calculates the measured data to establish a digital library for product stacking in the loading area. The central controller transmits the stacking model data through the connection of the background communication protocol. To the on-site controller, the controller controls the equipment to perform the specified stacking action through the received data packet to complete the loading process. On-site or control room is equipped with electronic kanban to display vehicle and online loading information in real time.

| Loading parameters |

Vehicle Specifications |

Loading efficiency | |

|

box truck |

The net width in the compartment is 1850-2300mm | up to 90 tons/hour | |

|

Fenced flatbed truck |

The net width in the compartment is 2250-2350mm | up to 120 tons/hour | |

|

Package weight |

500-2000kg/bag (ton bag) | ||

|

box truck |

The net width in the compartment is 1850-2300mm | up to 130 tons/hour | |

|

Fenced flatbed truck |

The net width in the compartment is 2250-2350mm | up to 160 tons/hour | |

|

Remarks: According to the on-site loading method, packaging size, stacking form, and specifications, it can be customized according to customer needs. |

|||

Video case

Online