Packaging Palletizing

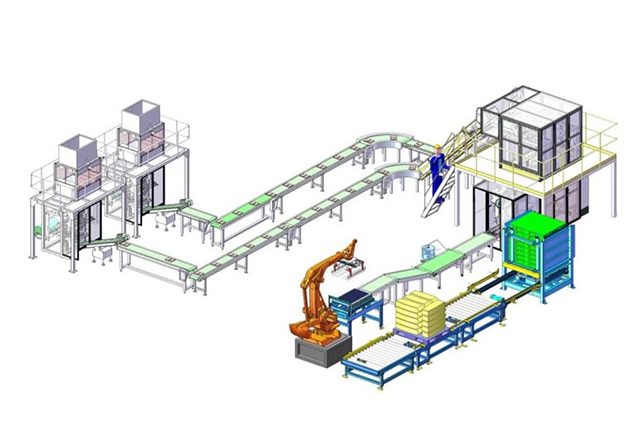

The automatic metering and packaging system is widely used in the automatic quantitative packaging of various packaging bags, such as paper bags, plastic bags, woven bags, etc. Its products are widely used in petrochemical, plastic, rubber, fertilizer, grain, food, medicine, feed, building materials, feed, environmental protection, minerals, new materials, metallurgy, ports, logistics and other industries. It is a full-process automation equipment that integrates automatic quantification, packaging, labeling and sealing (seam) transportation, weight detection and other equipment for bagged items such as materials. Suitable for large bags of 25kg-50kg nylon woven bags, paper-plastic composite bags, etc. are all packed in standard bags, which can realize continuous production and high-yield automatic bagging (sleeves) measurement packaging. The equipment can be combined with weighing scale conveyors and automatic sewing machines. Closely cooperate to complete the integrated automatic operation of bagging, weighing, bagging, conveying and sewing. Free people from heavy and repetitive work.

The robot palletizing production line is widely used in the palletizing of various bags and boxes. It is convenient and flexible, and has a wide range of applications. It can be used with multiple mobile lines and has a simple structure. It is equipped with different manipulators (fixtures, tooling) to complete the corresponding work. According to the shape of the object, different manipulators are installed to cooperate with the palletizing, which has the characteristics of strong changeability and wide application. Currently used by many industries.

● Robotic palletizing unit for bags

Uses: It is widely used in the automatic palletizing of bags in the industries of grain, feed, fertilizer, building materials, chemical raw materials, etc. Automatic sorting (arranging) and stacking of layers, supporting automatic pallet supply system and unloading conveying, only need forklift to remove the unloading pallet.

Select the model of the brand robot according to customer requirements, such as: ABB series robots, KUKA series robots, Kawasaki series robots, FANUC series robots, Fuji series robots, etc. The matching conveyor line can be customized according to the on-site connection.

● Box-loading robot palletizing unit

Uses: It is widely used in the automatic palletizing of boxes in food, beverage, edible oil, clothing, parts, chemical raw materials and other industries. Waiting for rows, automatic sorting (arranging) and stacking of layers, supporting automatic pallet supply system and unstacking conveying, only forklifts need to remove the unstacking pallets.

Tel:

(+86) 0551-65650713

Advantages compared with manual batching

"Three highs": high speed, high precision and high reliability;

High efficiency: robot palletizing is efficient and compact, with less floor space;

Cost reduction: unmanned, fast and stable automatic bagging work can be achieved, reducing labor costs and improving packaging production;

Good controllability: through the PLC network communication interface, central centralized control and remote network monitoring can be realized.

technical parameter

|

Type of metering packaging material |

|||

|

Granular material |

Powdery material | ||

|

Weighing range |

10kg ~ 50kg | Weighing range | 10kg ~ 50kg |

|

packing speed |

750 ~ 850d/h | packing speed | 550 ~ 750d/h |

|

Weighing accuracy |

±0.2% | Weighing accuracy | ±0.2% |

|

Feeding method |

Pneumatic double door feeding method Belt Multi-Stage Feeding Double vibrating feeding |

Feeding method | Double helix multi-stage feeding method belt feeding Combined feeding |

|

Accuracy and speed depend on material properties |

Accuracy and speed depend on material properties | ||

|

Palletizing capacity |

600d/h ~ 800d/h | Depends on the stacking layer height of the material and the weight of the bag | |

|

voltage |

380V ± 10% / 50Hz | ||

|

Self-inflicted power consumption |

8 kw/h ~ 20 kw/h | Depending on the combination of packaging material characteristics and equipment | |

|

Air supply source |

8.0 Mpa | Each part of the system is equipped with decompression and partial pressure devices | |

|

Maximum air power consumption |

3 m3/h ~ 4 m3/h | Depending on the combination of packaging material characteristics and equipment | |

Automatic quantitative packaging technical parameters

|

Packing weight (Kg) |

Packing speed (bag) | Measurement accuracy | Applicable packaging materials |

|

10~50 |

650~750 | 0.2 | Various powder materials |

|

10~50 |

750~900 | 0.2 | All kinds of granular and powdery materials |

|

10~50 |

550~650 | 0.2 | All kinds of powdery, lumpy and granular materials with high moisture content |

|

10~50 |

550~750 | 0.2 | Various special materials |

|

Packing weight (kg) |

Packing speed (bag/hour) | accuracy | Dimensions (m) L*W*H | Weight about (kg) |

|

10-60 |

300-350 | 0.2 | 3.0*0.8*2.2 | 450 |

|

10-60 |

600-750 | 0.2 | 4.5*2.1*2.8 | 650 |

|

10-50 |

180-240 | 0.2 | 3.2*2.0*2.5 | 500 |

|

10-50 |

450-600 | 0.2 | 4.5*2.1*3.2 | 750 |

|

name |

Basic parameters | Remark |

|

snatch weight |

140kg | Weight 50kg including hand |

|

Palletizing layers |

5~10 floors | Depends on bag and box material |

|

Palletizing speed |

800~2000 bags | Single-line, double-line palletizing can be set, mobile palletizing |

|

Layer ordering (orchestration) form |

self-selected | Regular 3+2 (5 bags per layer) 3+3+4 (10 bags per layer) |

|

Power consumption (Kw) |

3Kw ~ 8Kw | Depends on the robot brand |

Video case

Online