Automatic ingredients expert -Zhongke Kezheng

Release date:2022-04-26 Source:ZHONG KE KE ZHENG Views:1233

A, description,

Automatic batching is an automatic batching system used in industrial production. Usually a computer with automatic batching algorithm software as its automatic batching control system. Multiple scales can be controlled at the same time to control the output of different materials. Operation has intuitive, clear, automatic recovery function; Powerful report function, can record a large number of all kinds of data and tabulation printing; Good reliability; Powerful alarm prompt function, can reduce the rejection rate to the lowest degree; Equipped with on-line automatic monitoring software, through the real-time on-line monitor, monitoring the important information of production at any time. In the automatic batching system has a very wide range of industry experience, very deep r & D ability, has been widely recognized by customers.

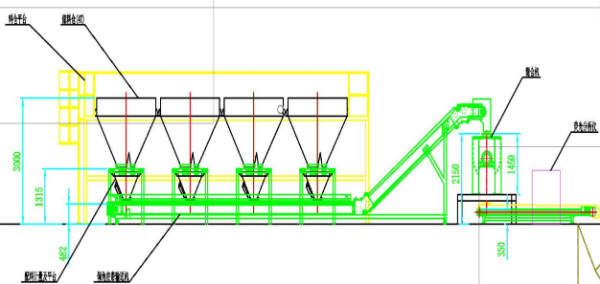

Conventional structure of automatic batching system

1. Static ingredients

Apply to batch ingredients allowing time intervals

It is a kind of automatic batching device which can be used with B fertilizer equipment, organic fertilizer equipment, compound fertilizer equipment and compound fertilizer equipment, and can complete automatic proportioning according to customer needs. This machine is used for weighing, distributing and mixing various raw materials separately instead of manual weighing or volume measurement. It has the characteristics of high measurement accuracy, fast distribution efficiency and high degree of automation, and is one of the main parts of complete set of fertilizer production equipment. The product adopts microcomputer control, electronic monitoring, digital prompt, good control function, easy to operate, is the guarantee of precise fertilizer product content.

2. Dynamic material is suitable for selling ingredients

The continuity of ingredients is higher, generally not allowed to stop the middle ingredients, the proportion of various materials is more strict requirements. The dynamic batching system generally uses electronic belt scale, electronic spiral scale, Coriolis scale and so on as the measuring equipment, the host has PID regulation and alarm function, can realize the automatic control of a warehouse.

3. Static and static combination

Special process requires continuous feeding of batch ingredients.

Some industries have special process requirements in batching, and need dynamic and static combination mode batching, so as to achieve the final process requirements. According to the requirements of batching process, parallel mode can be adopted in the control process, which can meet both high-precision micro-batching and continuous material batching with large proportion. Therefore, it can save batching time and meet the requirements of batching speed and accuracy.

Three, industry application

At present, automatic batching production line is widely used in food, metallurgy, building materials, chemical industry, rubber, civil explosive, new materials and other industries. And with the development of China's industrialization, more and more industries will be more deeply embrace automated ingredients system!

Iv. Technical advantages of the automatic batching system

1. Stable

Good control performance and high stability.

2. Efficient

Short batching cycle, fast speed, high capacity.

3. The convenient

The operation of industrial control platform is intuitive and convenient.

4. Security

Data storage security, good confidentiality.

5. Science

Real-time statistics, report retrieval, convenient traceability.

6. In a timely manner

Online monitoring fault prompt alarm.