Analysis of technical characteristics and entry barriers of intelligent automation system integratio

Release date:2022-03-03 Source:ZHONG KE KE ZHENG Views:793

Analysis of technical characteristics and entry barriers of intelligent automation system integration equipment industry

1. Industry development status

The intelligent automation system integration equipment belongs to automation equipment, which originates from the traditional production line (assembly line)—that is, a mechanical conveying system that completes the set production process in sequence by configuring operators or industrial robots. With the development of advanced industries, large-scale, personalized, flexible, and fast-paced manufacturing has become the mainstream of manufacturing. The traditional mechanical conveying system and information control technology are gradually integrated, and their functions are continuously expanded, becoming not only limited to conveying, but also Intelligent automation system integration equipment with various functions such as perception, analysis, reasoning, decision-making and control, and has gradually been widely used in modern industries such as home appliances, motorcycles, automobiles, modern warehousing and logistics, construction machinery, and rail transit. The integrated equipment industry came into being and is currently in the growth stage of the industry.

Due to years of industry habits, intelligent automation system integration equipment may still be referred to as "production line" for short, and the emphasis is mostly on conveying, so it is also called "intelligent conveying equipment", but its actual function has long exceeded the definition of "production line". And the "transport" function. The current intelligent automation system integration equipment is more intelligent, more environmentally friendly and more efficient, and has more comprehensive service capabilities due to system integration, and has been widely used in industry, agriculture, transportation, military, scientific research, commerce, medical services and other fields , belonging to "equipment in equipment" and "machine in machine", basically every downstream industry that enters the stage of large-scale production or needs automated production needs to use it. Therefore, in terms of function and system integration level, it is more suitable for the title of "intelligent automation system integration equipment", emphasizing "intelligence" and "system integration" because it is a branch of automation equipment, and it also highlights its various functions and individual constituent subsystems.

my country's intelligent automation system integration equipment industry started in the late 1980s. With the development of modern industrial manufacturing and industrial structure adjustment, through the introduction, digestion and absorption of foreign advanced technology experience and independent innovation, domestic intelligent automation system integration The application fields of equipment continue to expand, from home appliances, motorcycles, to automobiles, modern warehousing and logistics, construction machinery, rail transit and other production fields. The intelligent automation system integration equipment industry has also emerged a number of strong capital, with comprehensive capabilities such as providing complete research and development, design, manufacturing, installation and after-sales service, and in a downstream production field or a certain type of products provided have relatively Domestic enterprises with strong competitive advantages, such as Hubei Huachangda Intelligent Equipment Co., Ltd., mainly focus on providing intelligent automation equipment systems in the field of automobile production, and have a high market share in the field of domestic automobile automation equipment; Hubei Sanfeng The bicycle suspension conveying system produced by Intelligent Conveying Equipment Co., Ltd. has reached the international advanced level, ranking first in the domestic market share for three consecutive years. The first-mover advantage has been established in the field of bogie maintenance; in addition, domestic advantageous enterprises such as Jiangsu Tianqi Logistics System Engineering Co., Ltd. and Shanxi Dongjie Intelligent Logistics Equipment Co., Ltd. have also established their own comparative advantages in the industry.

In general, after more than 20 years of development, the domestic intelligent automation system integration equipment industry has produced a number of domestic-funded enterprises with good system integration capabilities, and some of the products provided have even reached the world's advanced level. Enterprises only have low system integration capabilities, and the products provided are mainly concentrated in the middle and low end; high-end intelligent automation system integration equipment such as chip packaging system equipment, large-scale logistics distribution sorting system equipment and other fields are basically developed by Europe, America, Japan, etc. It is monopolized by the country's enterprises, such as Germany's Siemens, Germany's Dürr, Germany's AFT, ABB, Japan's Daifuku Co., Ltd., etc.

2. The technical level of the industry

As a capital and technology-intensive industry, the intelligent automation system integration equipment industry is closely related to the overall technical level of a country's economic development level. In general, the intelligent automation system integration equipment technology represented by developed countries such as Germany, the United States, and Japan represents the most advanced technology in the world. R & D, manufacturing and other technical advantages. There are many enterprises in the domestic intelligent automation system integration equipment industry. Most of them only have the R&D and design capabilities of simple systems or standard products. The system integration is low. The products provided are mainly concentrated in the middle and low-end. Intense industries, such as motorcycles, food industries, etc., lack the technical strength to open up new fields, such as non-standard design, system integration, digital manufacturing, flexible production layout and other technologies. Some domestic-funded advantageous enterprises in the industry already have strong comprehensive system integration capabilities, and have outstanding non-standard design capabilities for different customers, and can compete with foreign capital in some high-end products.

3. Industry technical characteristics

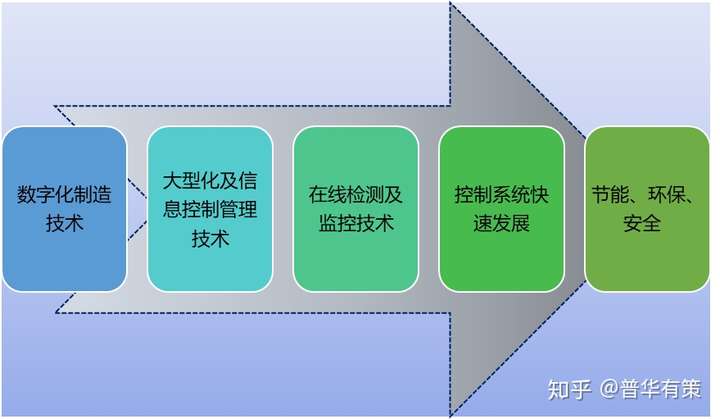

With the continuous changes in downstream industry demands and the continuous integration of information technology and intelligent automation system integration equipment, the technology of intelligent automation system integration equipment industry gradually presents the following trends:

Main technology trends of intelligent automation system integration equipment industry

(1) Digital manufacturing technology

Enterprises use "digital factory" (DF) software to establish an information platform for product manufacturing process, and then combine with resource management information platform and product design information platform to form an information platform that supports the complete manufacturing process of enterprise products. Since the design, manufacture and maintenance of the intelligent automation system integration equipment are all simulated on this information platform, process synchronization and information sharing are realized, and the modularization and standardization of the design can be used to quickly realize the adjustment and readjustment of the intelligent automation system integration equipment. Therefore, it can compress the production time to the maximum extent and meet the requirements of downstream customers for the flexibility and quality control functions of intelligent automation system integration equipment.

(2) Large-scale and information control management technology

The large-scale intelligent automation system integration equipment refers to the development and manufacture of more complete large and heavy-duty intelligent automation systems suitable for the assembly from fixed station to assembly line for several industries such as large-scale product manufacturing and assembly in downstream industries, such as rolling stock, aviation, and shipbuilding. Integrated equipment, some western developed countries have begun to produce such large-scale equipment. Information control management technology refers to the use of various high-tech and design methods such as CAX and simulation systems to rapidly design and develop large-scale intelligent automation equipment, and conduct digital verification. .

(3) Online detection and monitoring technology

It refers to the use of intelligent technologies such as sensors and robots to realize the online detection function of large-scale intelligent automation system integrated equipment, and to realize active control of product quality; the use of network technology to realize the online monitoring function of intelligent automation system integrated equipment to ensure the safe operation of production equipment.

(4) Rapid development of control system

It mainly includes two meanings: A. The control system develops from centralized to decentralized, and intelligent distributed I/O will form a certain part of I/O into an autonomous node, which has its own processor and independently completes a certain part of the operation. Control; B. As a supplement to wired control systems, wireless communication technology is being continuously applied to industrial automation systems. At the same time, the human-machine interface is more humanized, providing more and more information for operators and managers.

(5) Energy saving, environmental protection and safety

In addition to high efficiency requirements, the main goals of automation driven by information technology include energy saving, environmental protection, and safety goals. The specific contents include reducing dust, noise, exhaust gas and other pollutants that may be generated by various intelligent automation system integrated equipment during operation. Reduce energy consumption to save sources; at the same time, the equipment can work in the environment with corrosive, radioactive and flammable substances under high and low temperature conditions, and can transport hot, explosive, easy to agglomerate, viscous materials, etc. . Safety production has become an important indicator to measure modern industry. The main safety considerations of automation control systems are: electrical safety, explosion-proof safety, information safety and functional safety. Information safety refers to the prevention of information leakage, hacking and other factors. System safety Sexual risks; functional safety refers to the prevention of hazards caused by the failure of the safety functions performed by the control system.

4. The main barriers to entering the industry

Due to the difference in downstream industries, intelligent automation system integration equipment is usually non-standardized products, that is, enterprises need to conduct product research and development, design, manufacturing, and provide products according to the different production environments, production processes, and production parameters of downstream customers. It often belongs to the "first set" in the industry, and the process of providing products is often the process of research and development by companies in the industry. Therefore, the intelligent automation system integration equipment industry has high industry barriers, which are embodied in the following aspects.

(1) Talent Barriers

Since the intelligent automation system integration equipment is a product involving many disciplines and technologies, it is necessary to have a large number of high-skilled talents of different professions for division of labor, including system design talents, mechanical and electrical design and manufacturing professionals, software programming professionals, and rich project management. Experienced project managers and professional sales personnel; at the same time, the non-standardized characteristics of intelligent automation system integration equipment require all kinds of professionals to have profound industry experience accumulation, and can propose feasible product solutions for the needs of different downstream customers.

(2) Barriers to comprehensive capabilities of system integration

The intelligent automation system integration equipment industry is a technology-intensive industry involving many disciplines and fields. The disciplines involved include machinery, electrical, automatic control, computer, information engineering, etc. The downstream application areas include rail transit, construction machinery , automobiles, special equipment, motorcycles, modern warehousing and logistics, home appliances, chemicals, medical equipment and many other industries and fields. Different downstream application fields have different specific application environments, product production processes, and logistics transportation forms. The components of the equipment that constitute the subsystems are also different. Therefore, enterprises in the industry must have excellent comprehensive system integration capabilities. On the basis of understanding and mastering cutting-edge technologies and deeply understanding the different needs of downstream customers, they can design and manufacture products that meet customer needs or even exceed customers. The expected intelligent automation system integration equipment.

(3) Design capability barriers

Due to the non-standardized characteristics of intelligent automation system integration equipment, design capability has become an important indicator to measure product quality, which is mainly reflected in the following two aspects: In the bidding stage of downstream customers, enterprises in the industry need to Factors such as production technology design the overall equipment, including the overall composition scheme, overall spatial layout, overall installation scheme, etc.; in the production and processing stage, it is necessary to determine the composition of the subsystems according to the different production parameters of downstream customers, such as load capacity, production rhythm, etc. The processing technology, control function, software function, etc. of various types of machinery are designed, which requires many years of industry design experience accumulation and advanced design guarantee methods.

(4) Financial barriers

The intelligent automation system integration equipment industry has high requirements for capital, which is mainly reflected in the following aspects: intelligent automation system integration equipment is usually a non-standard product, and enterprises in the industry often need to invest in their own products after placing an order. R&D, additional R&D expenses are not included in the price of the product. If the enterprise does not have deep technical accumulation and strong financial strength, long-term product R&D will form a larger capital occupation for the enterprise, which will affect the operation of the enterprise. Pressure, but also affects the acceptance of future orders; secondly, the price of a set of intelligent automation system integration equipment is generally more than 10 million yuan, enterprises need to advance most of the funds for pre-production, and customers will only pay after the installation, commissioning and acceptance are qualified. Most of the money, so it is difficult to enter this industry without a certain financial strength; finally, the production of intelligent automation system integration equipment requires fixed workshops, precision machining equipment, advanced three-dimensional design studios, etc., and requires large investment in fixed assets.

(5) Barriers to downstream industries

The intelligent automation system integration business is closely related to the downstream industry, and the entry barriers of the downstream industry indirectly affect the enterprises in this industry.

Taking special equipment as an example, the barriers to the military industry are very high. In addition to their own technical and operational strengths, enterprises may also need to pass the national military standard quality management system certification, weapon equipment scientific research and production unit confidentiality qualification certification, and weapon equipment scientific research and production licenses. Certificate certification, equipment manufacturing unit qualification directory certification. Enterprises in this industry provide military enterprises with intelligent automation system integration equipment for the production of special equipment. If the project has a significant impact on the defense industry, it may also need to have corresponding certification.

(6) Barriers to customer resources

The production process of intelligent automation system integration equipment itself is the process of research and development by enterprises in the industry. Therefore, the products provided often have the nature of "the first set" in the industry. There is a good demonstration effect among other customers. For the reasons of quality, efficiency and safety, downstream customers will give priority to companies with experience in providing this product.

Source: PricewaterhouseCoopers